| ||

|

||

|

|||||||

| Water Block Design / Construction Building your own block? Need info on designing one? Heres where to do it |

|

| Thread Tools |

|

|

#1 |

|

Cooling Neophyte

Join Date: Aug 2005

Location: Canada

Posts: 12

|

[Pulling this thread off of XS, want to know your guys' expert opinion]

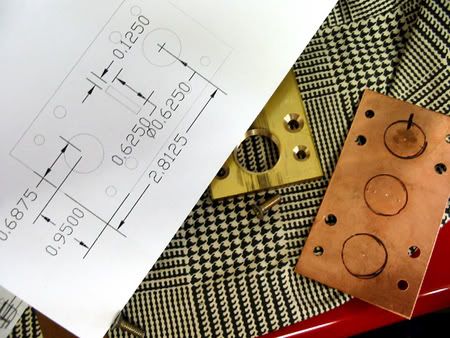

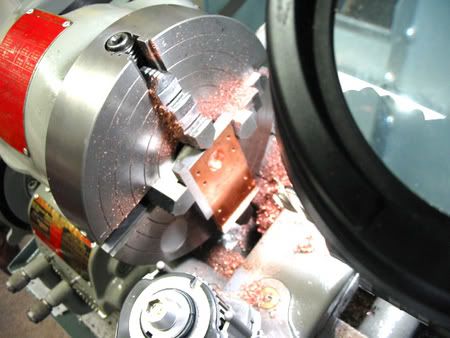

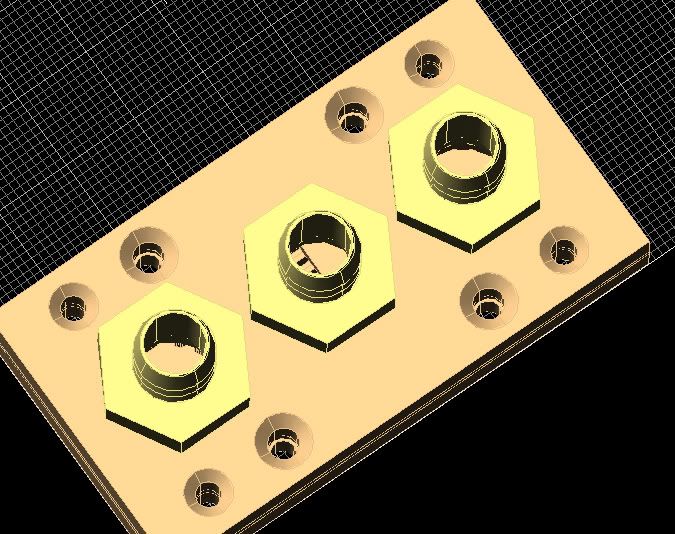

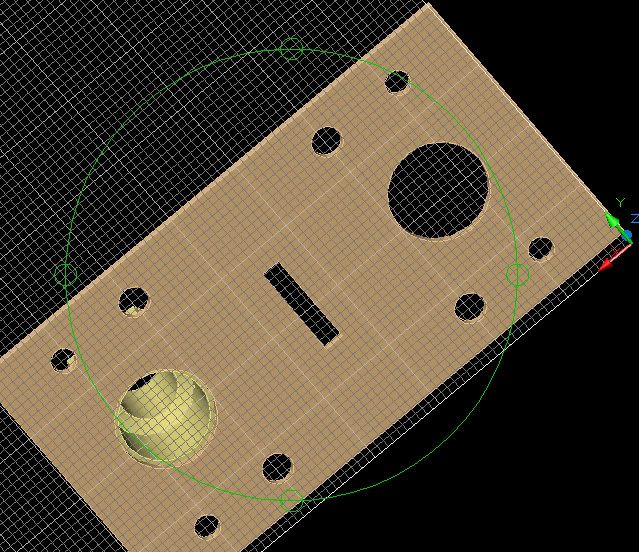

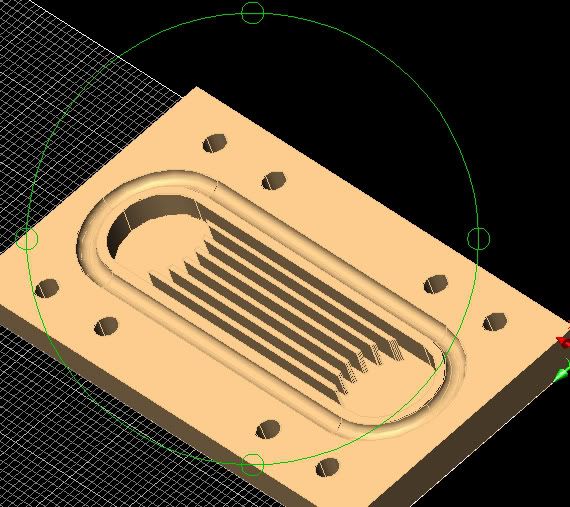

Okay, I though I'd post this somewhere since my waterblock design is almost done! Once I get some 1/16th endmills and a rounded-end 1/8th for the o-ring slot I can do the channels down the middle and finish it up, then hook it up with the rest of my ghetto watercooling and be done. Not much else to say right now, except for that I've been making the block on a lathe and it's (pretty much) copying Cathar's Whitewater (I think). During the process I found out that copper is a biatch to machine (when adding fluid to the cut it wouldn't even cut). Next time I'd start it off with a boring bar then oversize it from there.        Hope to get it done within the next couple of weeks, when the mills come in. My dad made me a holder on the lathe so that we can grab a high speed (15k RPM) tool, then grab the tiny endmill within that, and cut the 7-8 channels (I forget exactly how many are in the design). Well, anyway, here's the design for reference.    Thanks for reading, comments are welcome. |

|

|

|

|

|

#2 |

|

Put up or Shut Up

Join Date: Dec 2001

Location: Spokane WA

Posts: 6,506

|

Looking good.

Note the O-ring grove should not be rounded on the bottom like you suggest. Reference: http://www.spira-emi.com/mainpages/groovemtg_main.htm http://www.efunda.com/designstandard...ring_intro.cfm |

|

|

|

|

|

#3 |

|

Cooling Neophyte

Join Date: Aug 2005

Location: Canada

Posts: 12

|

It'd still seal with a rounded groove though, wouldn't it? If I'm using a 3/32" o-ring or whatnot, then putting in a 1/8" rounded groove to the right depth, the o-ring would squish to shape, right?

Also, I need an opinion on one part.. on the top piece (because there's a middle plate) instead of putting o-ring grooves, I just put little o-rings on the inside of the bottom of the barbs, and tightened down as much as possible. Leak or no leak? |

|

|

|

|

|

#4 | |

|

Put up or Shut Up

Join Date: Dec 2001

Location: Spokane WA

Posts: 6,506

|

Quote:

You need an o-ring on the outside of the barb holes on the middle piece on the top side. Or just one groove around them all? If your going to mill an groove in the base it will be the same groove on the top plate. All you have to do is take the base out and put the middle piece in and do it over. But however you want to do it. |

|

|

|

|

|

|

#5 |

|

Cooling Savant

Join Date: Aug 2005

Location: uk

Posts: 400

|

Not to much of rounding on the groove and it will be fine. As long as the ring can squish.

If the slit is thin ([21.2*flow rate of system / slit width (the smallest one)] is more than 100, try and get a good sf near the exit as it will improve perfromance slightly but a relatively poor finish on the end of the channels is fine. What ever you find that works best. I would highly recommend making a reducer insert that changes the nozzle diameter slowly if possible as it will save on head loss alot. Admitedly the geometary is awful but it will help. Getting a bar then milling an angle in it. Need to punch some numbers to get what a long enough section would be but any insert would help. Picking numbers out of the air, maybe 10 to 20% head loss recovery. Its a similar thing with the exit sections a nice curve section on the end of the mill (as much as possible) will save some head loss, but its probably too late now. I could always run it through cfd with dxf file if you want. I figure its relatively cfd able. |

|

|

|

|

|

#6 |

|

Cooling Neophyte

Join Date: Aug 2005

Location: Canada

Posts: 12

|

I'm thinking that it's restricted so much that it won't matter that the ends are a little off, and it's too late anyway (although I COULD make a whole new bottom piece).

About the reducer though, I could probably do that, take a piece of scrap copper/brass and mill it down to that. just don't know how I'd secure it in. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

All times are GMT -5. The time now is 01:12 AM.