| ||

|

||

|

|||||||

| Water Block Design / Construction Building your own block? Need info on designing one? Heres where to do it |

|

| Thread Tools |

|

|

#1 |

|

Cooling Neophyte

Join Date: Aug 2006

Location: Melbourne

Posts: 12

|

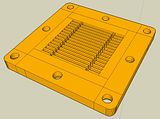

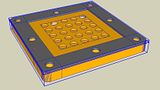

Hey all

First off i just like to say i've have never used watercooling before so most of this is pure guess work. -Just have a few questions about making a diy cpu block. I'm just trying to get a basic idea of what tools and materials are needed for a diy waterblock? -I have access to a basic hand tools (files, hacksaw etc) as well as a dremel, Bandsaw, bench grinder and a drill press, what other tools would be required for construction? -How difficult is it to make a basic waterblock? I'm not aiming to make a super duper trick cooling block, just something that will keep up with a stock hsf. Just to see what i could come up with i put together this design based on my basic knowledge.    The base plate is 55x55x5 The top and bottom plates would be made from copper while the middle would be plexi. The middle area with indents is 28x28. Middle plexi section is 7mm high with the top copper plate a further 3mm high. So based on that any ideas which part of that design would work well and what is in the totally wrong direction? Would an aluminium block perform dramatically different to a copper one? Any help is greatly appreciated. Last edited by crazylittleman; 08-26-2006 at 03:28 AM. |

|

|

|

|

|

#2 | |

|

Cooling Savant

Join Date: Jan 2006

Location: VA

Posts: 129

|

Quote:

I too am working on a fairly easy to machine waterblock design that you might be interested in: http://forums.procooling.com/vbb/showthread.php?t=13359 2. You already have the basics and will need to design your block with those tools in mind. I would however warn you that acrylic is very difficult to cut cleanly with rotary tools. Acrylic won't cut very easily with abrasive tools. I would recommend looking into getting a scrollsaw if you want to cut plastics. 3. Time consuming, but not the most difficult thing in the world to accomplish. Requires alot of patience. 4. Plexi isn't a material, but rather a family of plastics. If you want a very easy to machine and durable plastic I recommend using polycarbonate. It machines similarly to aluminum and has good chemical resistance. The only negative to using it is that you have to keep it away from bleech, which isn't something you should be putting in your loop anyways. Acrylic won't be too workable with any of your tools except for the bandsaw and drillpress. If you plan to do any interior cuts you may be able to do so with coarse stone griding tools, but not with cut-off discs. 5. You base piece is a little too thick and doesn't have a terribly effective channeling or pin configuration. Read around in this forum section a little more to get an understanding of what makes a block effecient and what does not. You could alter your design to make it similar to the #rotor with iron cross pins made with a combination of drilling and dremeling and you'll end up with a fairly decent block. 6. Aluminum has lower thermal conductivity and thermal capacitance. You also do not want to mix aluminum and copper in your watercooling loop if you can help it (most radiators for example are made from copper) as it will require you to add a higher concentration of antifreeze to your loop in order to stave off galvanic corrosion. Aluminum is a great material for heatsink fins because it bleeds thermal energy off faster than copper, but it's not as effective as a base material. Your measurements are heading in the right direction in that the base doens't need to be any larger than 55x55mm and only the center 30mm square needs turbulent flow from fins or pins. However you are lacking an effective set of fins or pins that penetrate into the base. |

|

|

|

|

|

|

#3 | |

|

Cooling Savant

Join Date: Sep 2005

Location: Virginia

Posts: 153

|

Quote:

In my understanding Cu (~400 W/mK) is a little less than twice as thermally conductive as Al(~240 W/mK). http://www.heatsink-guide.com/conten...sinkinfo.shtml I believe the reasons for the use of Al in HSF's is as follows: 1. it is cheaper than copper(recent trends) 2. it is about a two thirds less massive than copper and is therefore lighter 3. it is easier to work with than copper(quicker to manufacture with simpler processes)

__________________

I can't spell, but I am working on it. |

|

|

|

|

|

|

#4 |

|

Responsible for 2%

of all the posts here. Join Date: May 2002

Location: Texas, U.S.A.

Posts: 8,302

|

Actually, heat capacity is a key factor, along with the above, and machineability.

Copper would work very well as a heatsink (fin), but would have to be much thinner than its aluminium counterpart, and that leads us to the manufacturing aspect; the best process I've seen yet is shaved copper fins. Probably still expensive, but it's really hard to beat the cheap aluminium extrusion process that is so common (and cheap), and that unfortunately cannot be ported over to make thin copper fins. |

|

|

|

|

|

#5 |

|

Cooling Savant

Join Date: Aug 2005

Location: uk

Posts: 400

|

ppl did not make the comment that aluminium having a higher heat capacity than copper so its better, thats so hardocp :P

If bill were here he would be having a right moan. Thermal capacity (thermal mass if you will) is not useful in computer heatsink design. Has no useful effects. Its kinda like saying im going to stop the sink from overflowing from a running tap by getting a bigger sink. |

|

|

|

|

|

#6 | |

|

Cooling Savant

Join Date: Jan 2006

Location: VA

Posts: 129

|

Quote:

Say you take a copper heatsink and an aluminum heatsink, both with the same C/W rating and airflow, and then apply the same heat load for the same amount of time. When the heatload is removed the aluminum heatsink will reach ambient temperature faster than the copper. This works out positively when aluminum is used for air-cooling, but negatively in other applications such as waterblocks, phase-change evaporators, and Dry Ice/LN2 containers. Last edited by Captain Slug; 08-17-2006 at 06:33 PM. |

|

|

|

|

|

|

#7 |

|

Put up or Shut Up

Join Date: Dec 2001

Location: Spokane WA

Posts: 6,506

|

Copper will bleed off heat faster than aluminum. The thermal conductivity rating is proof of that. It cannot have a higher thermal conductivity if is bleeds off heat slower. The conductivity rating is how efficiently it transfers heat. The higher the number the more efficiently it transfers heat. More efficiency means faster transfer rates.

I think were you are getting confused is the thermal capacity rating. Copper has a higher thermal capacity. This means it will take a lot longer to bleed the heat off because more is stored in the copper. |

|

|

|

|

|

#8 |

|

Cooling Savant

Join Date: Jan 2006

Location: VA

Posts: 129

|

Stupidity confirmed. I was pretty mixed up on how the two relate to eachother but I think I have it straightened out in my head. Aluminum only reaches ambient faster because it won't reach as high a temperature as a copper heatsink of similar c/w on the same heat load. So the copper heatsink has a higher temperature range to cross.

|

|

|

|

|

|

#9 |

|

Cooling Neophyte

Join Date: Aug 2006

Location: Melbourne

Posts: 12

|

Last edited by crazylittleman; 08-26-2006 at 03:30 AM. |

|

|

|

|

|

#10 |

|

Cooling Savant

Join Date: Jan 2006

Location: VA

Posts: 129

|

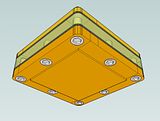

That's more like it. How thick is your base piece (total)?

You might want to make your "slot" depth 3mm and the "floor" of you base 1.5mm or 2mm |

|

|

|

|

|

#11 |

|

Cooling Neophyte

Join Date: Aug 2006

Location: Melbourne

Posts: 12

|

I was aiming to make the base 5mm thick total but this may change depending on what copper i can get when it comes to construction. The final slot depth will be based on the base thickness.

Last edited by crazylittleman; 08-18-2006 at 06:24 AM. |

|

|

|

|

|

#12 |

|

Cooling Neophyte

Join Date: Aug 2006

Location: Melbourne

Posts: 12

|

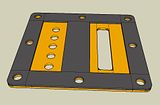

Just procrastinating homework and had a play around with sketchup again.

In the left out on the right. I put together the design for this plate. The basic idea was to intoduce more turbulence into the inflow. Last edited by crazylittleman; 08-26-2006 at 03:30 AM. |

|

|

|

|

|

#13 |

|

Cooling Savant

Join Date: Jan 2006

Location: VA

Posts: 129

|

If you're going to have nozzles they will really only be effective if near the center. So if you're sticking with two barbs you may need to make an offset center in order to do that.

|

|

|

|

|

|

#14 |

|

CNC Beyatch

Join Date: Aug 2001

Location: Tulsa Spell it backwards

Posts: 721

|

I want to know how your going to cut the 1 mm channels..... please enlighten me! I really want to know

__________________

Creator of the Spir@l Block Longest post ever http://forums.procooling.com/vbb/showthread.php?s=&postid=43808#post43808 |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

All times are GMT -5. The time now is 06:47 PM.