I've been wanting to design a waterblock for a while now. Regardless of whether this amounts to anything or not I'm designing what I can based around what tools I have access to (Manual Mill, Machine Lathe, Drillpress).

Just trying to get feedback on my design. Hit me hard because I've never done this kind of design work before and just wanted to get this concept out in the open.

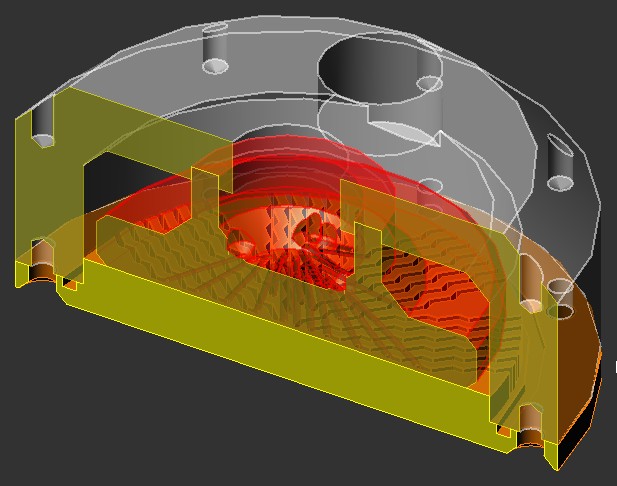

I've also been doing alot of reading in this forum and even though I started out hoping to do a round waterblock I came upon BigBen2k's thread thanks to nikhsub1. I found the thread very helpful and what I learned from that thread specifically lead to a dramatic change in my block design.

This was the precursor that helped me figure out what I was trying to acheive.

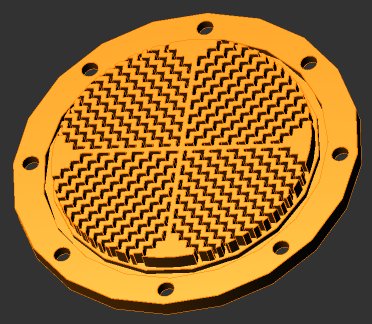

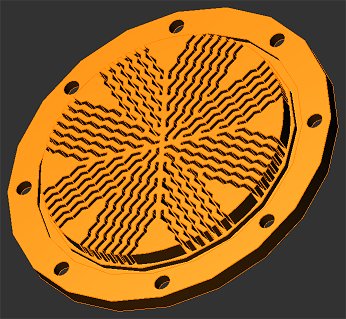

Dimensions: 2.5" Diam. x .25" thickness

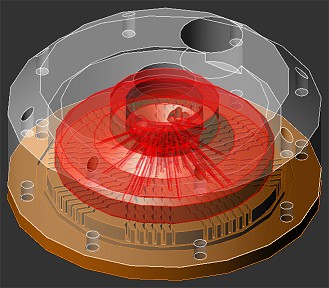

After determining what kind of pattern I wanted to use and experimenting with channel spacings I finally managed to figure out a 45-degree pattern that I'm happy with. The new design has 10 more channels, with 52 total. All at 1.4mm width. (the "fins" end up with the same width). I'll use a technique of print-out transfer normally used for PCB etching to act as a template for drilling and milling the channels.

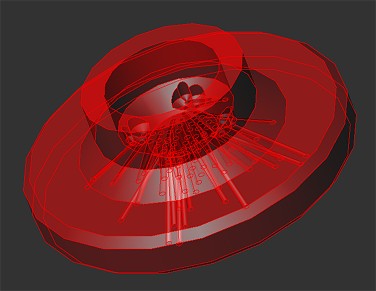

The collimater has 52 angled nozzles (13 different angles), which I'll have to drill by using a combination of an angle vice and a drill press.

The jets in the center will have the most turbulence do to their entry angle but the center is contacted heavily by the majority of the nozzles.

And I need to design the mounting bracket still, which will bolt flush with the top of the waterblock.

It's going to be a huge PITA to make but I'm sure I can manage it with what tools I have access to.