Actually I screwed up the compression fittings. I couldn't get a working thread on them with the die blocks. So if I want to make them the way I intended them to be I'd have to start over again.

After some fiddling about yesterday I discovered that the collar nuts that I hadn't finished making for the compression fittings make some strangely effective tubing clamps.

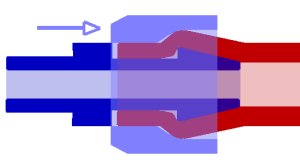

You slip the collar nut around the fitting, slide the tubing onto the fitting, then pull the collar nut onto the tubing like so.

What I end up with is basically like chinese hand-cuffs. The harder I pull on the tubing, the harder the collar nut clamps the tubing to the fitting. The tubing cannot be pulled off the fitting with the collar inplace because the inner diameter of the collar nut fits the outside of the tubing so precisely that the tubing can't get over the lip on the barb. To unclamp the tubing you just push the collar nut away from the tubing.

I've accidentally made a backwards compression fitting. I want to do some leak testing with these, the pump, and one block later.

If I want to attempt making compression fittings again I'll have to use the lathe to add the thread to the fittings rather than trying to do it with the die blocks.