| ||

|

||

|

|||||||

| General Liquid/Water Cooling Discussion For discussion about Full Cooling System kits, or general cooling topics. Keep specific cooling items like pumps, radiators, etc... in their specific forums. |

|

| Thread Tools |

|

|

#1 |

|

Cooling Neophyte

Join Date: Jun 2001

Location: MA

Posts: 1

|

I am strongly considering a watercooling setup, but I have some serious reservations.

Primarily, I'm concerned that if for some reason my watercooling equipment is not running, for some failure or any other reason, I won't be able to run the system. Thus, my computer will be hostage to the watercooling setup. BUT, what if a HSF is mounted to the waterblock? Assuming flat surfaces and a good bond, as with Arctic Silver, it seems that this would be a good backup. I realize that the waterblock is hollow, but if filled with water should conduct reasonably well. What do you think? |

|

|

|

|

|

#2 |

|

The Pro/Life Support System

Join Date: Dec 1999

Location: Denver, CO

Posts: 4,041

|

It will work to a point. what you will have is an extremely hot block wiht a HSF on top. the HSF MAY help keep the block cooler and keep the core from fry'n. But I wouldnt plan on it saving yer system.

Any HSF on top of the block will lower overall performance as it will conduct heat from sorrounding elements and air to the coolant also, lowering your overall cooling ability. ( main reason the CPUFX Reactor aint so great. ) Just keep a spare HSF around incase the cooling gear does fail in some way, then you can take the block off, and put a HSF on. Best precaution is just to buy reliable and good quality cooling gear.

__________________

Joe - I only take this hat off for one thing... ProCooling archive curator and dusty skeleton. |

|

|

|

|

|

#3 |

|

Cooling Neophyte

Join Date: Jun 2001

Location: new zealand

Posts: 31

|

If you use mbm program to monitor your temps then you can use the shutdown now program that works in conjunction with it, so your able to set a trigger for your desired overheat setting that will shut down you pc in case of a melt down.

stevo

__________________

I found a virus on my computer it's called "windows" chancell@ihug.co.nz |

|

|

|

|

|

#4 |

|

Cooling Neophyte

Join Date: Jul 2001

Location: Anchorage

Posts: 3

|

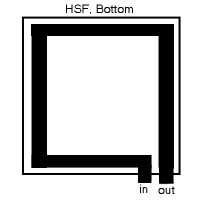

I am working on getting an HSF (Air) and water cooled combination heatsink. I am considering my Swiftech 462-A heatsink as the best candidate for this. Rather than sandwiching in a water plate I won't use one at all but rather convert my HSF into a dual acting air and water cooler by boring out holes through all four courners of the copper heatsink base to form an internal loop within the formally only air heatsink to add a channel for water to flow through its copper base. I intend on using the largest diameter drill bit that I can possibly use without cutting too close to the outside edges of the copper block.

I think that this can be done very easily using just a drill press and some taps. I intend on drilling a hole laterally through the copper portion of the HSF block, or another way of looking at it is that I will be drilling out material within the same plane of the heatsink base, all the way around, one hole per side (All four sides) and then tap each hole with threads to accept two fittings for the "in" and "out" couplings and then blocking two of the holes on one side so that it becomes a loop inside of the copper plate. Obviously, all four of the drilled out chambers need to connect but this should be easy enough since your drilling all the way through each side, you can't miss. You could also just drill some holes completely through one side to the other, several of them and join all the holes together on each side so that the water would run through several joined holes in and out, having them "T" together where the water enters and leaves the core. THis would be just a strait through shot in this configuration rather than a loop around the outer rim of the copper base. I suppose you could drill out up to about 25% or more of the copper base this way and likely have very little effect upon the air cooling function of the heatsink. I would only consider this as an augmentation to further reduce the cooling below what air alone would do. This will allow the unit to keep on cooling even if you had no water flowing and cool nearly as well, if not the same as it did before. However with water flowing it ought to cool considerably better than air alone. It makes sense to me that all water blocks should be both air and water combinations for redundancy against failure of either the fan or the water cooling system. You could run a quiet fan this way. If the water circulation failed it would be hot, but not so hot to hurt anything. With only a fan failure and water flowing it ought to still be cool enough to use. I don't know if a water block can be designed for maximum cooling when tooled for both air and water cooling. But, I do believe that the Swift 462-A can be tooled for water flow around the edges of its massive copper block and make it a much cooler HSF and allowing replacement of that damn noisey fan with a quieter one while runing much cooler at the same time.  You could also just take some copper pipe and wrap it around the outside edges of the heatsink base and solder it on real well, it ought to work too but not nearly as well because most of the copper pipe with its cool water would be hanging on the outside of the HSF's copper core only having one side of the copper loop touching the heatsink where its soldered to the four sides. Boring out four holes within the horizontal plane of the heatsink base is the same thing as soldering on a loop of copper pipe around the outside edges of the HSF base, except by boring out an internal loop (Making a loop when the two blocking plugs are installed.) for water to flow through, all of the water runs through the HSF's copper core right at its base near the CPU. I am willing to bet that if one manufacture builds something like this, it will catch on and a lot more people will consider water cooling as an option for them. People consider fans as more reliable than water cooling, which they are just because they are so simple compared to water cooling. Don't misunderstand, if you do your water cooling right your fine and it can be reliable. But what scares off the newbies is that they know they are newbies and are afraid to risk their CPU to a water flow problem. The air and water heatsink combination ought to remove this major block in peoples minds. I'm fresh from newbie world, I know. Having said that, I believe that my thoughts on all of the above are correct, even if I have never done this  Late EDIT: I posted this subject over at arstechnica.com and "clm100" posted back with the following image:  Seeing this, I now understand that I couldn't drill four holes, one through each side of the square heatsink base because there would be no stop wall between the input and output couplings! However, it wouldn't be hard to do it this way. I have been pondering this some more, that Swiftech's copper plate on the base is only 3/8ths of an inch thick. It would be an awful small diameter hole to do this. Perhaps I should just "T" a whole bunch of holes running in parallel through the whole copper base except leaving the area where the CPU core would be alone so that I wouldn't totally ruin the air cooling capability, which after all is what I want, both for redundancy. I wouldn't want to core out too much percentage of the copper plate, 25% max. to maintain the air cooling ability. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

All times are GMT -5. The time now is 05:42 AM.