| ||

|

||

|

|||||||

| Water Block Design / Construction Building your own block? Need info on designing one? Heres where to do it |

|

| Thread Tools |

|

|

#1 |

|

Cooling Savant

Join Date: Jan 2006

Location: VA

Posts: 129

|

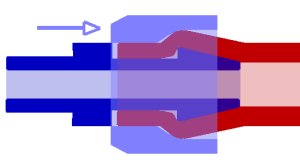

First a WARNING: These hose clamps will only work with single-barb fittings. To make these for other tubing sizes you will need to adapt the measurements. I made these specifically for 1/2" ID 3/4" OD because there's a complete lack of variety when comes to fittings for that size of tubing.

Here's how they work.  1. You slip the compression cuff over the barb with the narrow end away from the tubing (if you get this wrong you won't be able to get the tubing on) 2. Slide the tubing onto the barb and into the wide end of the compression cuff 3. Twist and pull the compression cuff upwards until the centerline of it is as close to where you think the underside of the barb head is. With clear compression cuffs this location becomes fairly obvious by how tight the narrow end of the cuff gets over the tubing. To remove reverse the process. I've done a bit of testing with these and they've worked great so far and I've decided to allow everyone to try making them.  This are REALLY easy to make with a lathe if you simply order 3/4" ID 1" OD polycarbonate tubing and then cut sections of it to length. It might be possible to make these with a drillpress if you have the right drillbit but I wouldn't recommend it.  .81" ID is what worked best with my tubing but the widened end is really just there to act as a lip to help wedge the tubing onto the underside of the barb head. That means to widen one end you'll need either a 25/32" or 13/16" drill bit or a boring rod. Some light sanding with 300grit sandpaper in the narrow end of the cuff will probably be required in order to allow it to slide on the tubing when dry. And the best part of all: These things are DIRT CHEAP TO MAKE. 8 feet of 3/4" ID 1" OD polycarbonate tube from mcmaster (part# 8585K35) costs a meager $3.78 and yields around 50 compression cuffs. The only noticable expense is time. I'd like to see more people test this for themselves and this is pretty much the only community I know of that has enough capable machinists that my be willing to try. Last edited by Captain Slug; 08-08-2006 at 12:11 PM. |

|

|

|

|

|

#2 |

|

Cooling Neophyte

Join Date: Jun 2005

Location: Blue Ridge Mountains

Posts: 44

|

Sweet work

__________________

Electronics are prefilled with factory smoke--if the smoke gets out they stop working--So Don't Let The Smoke Out! |

|

|

|

|

|

#3 |

|

Cooling Neophyte

Join Date: Feb 2006

Location: Western face of Mt. St. Helens

Posts: 25

|

Great job CS.

I've been pondering this design since you first happened on it with your compression fitting mishap in the Nazca thread.  Having a 1952 Delta Milwaukee drill press, rock solid at 130lbs, looks like I'll be attempting a few variations on your theme, in spite of your advice against it.  Would appreciate the depth measurements on the ID of both the 25/32 and 3/4 bores though. Cudos on providing further stats/motivation, will post results and learning curve of my drill press adventures.

Last edited by Dryadsoul; 08-08-2006 at 04:41 AM. |

|

|

|

|

|

#4 | |

|

Cooling Savant

Join Date: Jan 2006

Location: VA

Posts: 129

|

Quote:

The depth of the narrow end needs to be similar to the height of the hex collar on your fittings. Typically this is around 1/4" but the fittings you get from various watercooling suppliers will have a hex much thinner than that. For mine I just aimed at putting the transition between the two IDs in the middle. The narrow ends doesn't need to be very long in order to work. I also forgot to note that I HAVE made one or two of these out of brass. It's possible to make them out of aluminum as well. I prefer plastic because it's dirt cheap and way more "friendly" when it comes to machining. |

|

|

|

|

|

|

#5 |

|

Cooling Neophyte

Join Date: Feb 2006

Location: Western face of Mt. St. Helens

Posts: 25

|

Yeah, I was considering brass, but I much prefer the idea of the clear cuffs making these a totally user friendly/idiot proof product.

Thanks for the info. |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

All times are GMT -5. The time now is 07:01 PM.