| ||

|

||

|

|||||||

| Water Block Design / Construction Building your own block? Need info on designing one? Heres where to do it |

|

| Thread Tools |

|

|

#201 | |

|

c00ling p00n

Join Date: Jun 2002

Location: L.A.

Posts: 758

|

Quote:

__________________

*:-.,_,.-:*'``'*:-.,_,.-:*'``'*:-.,_,.-:*'``'*:-.,_,.-:*'``'*:-.,_,.-:* E6700 @ 3.65Ghz / P5W DH Deluxe / 2GB 667 TeamGroup / 1900XTX PC Power & Cooling Turbo 510 Deluxe Mountain Mods U2-UFO Cube Storm G5 --> MP-01 --> PA 120.3 --> 2x DDC Ultras in Series --> Custom Clear Res "Artificial intelligence is no match for natural stupidity." 1,223,460+ Ghz Folding@Home aNonForums *:-.,_,.-:*'``'*:-.,_,.-:*'``'*:-.,_,.-:*'``'*:-.,_,.-:*'``'*:-.,_,.-:* |

|

|

|

|

|

|

#202 |

|

CoolingWorks Tech Guy Formerly "Unregistered"

Join Date: Dec 2000

Location: Posts: 2,371.493,106

Posts: 4,440

|

difficult to say 'sad'

to Steve's credit he took a better read of the market than I, and delivered what they wanted and his management of the 'review process' has been masterful I'm the supposed know-it-all and look at the beating the MCW6000 got from JoeC this is not to say that the MCW6000 is not 'successful', just missed those needing the bling bling |

|

|

|

|

|

#203 |

|

Thermophile

Join Date: Sep 2002

Location: Charlotte, NC

Posts: 1,014

|

if you gold plate it, bling will come.

__________________

I have a nice computer. |

|

|

|

|

|

#204 |

|

Cooling Savant

Join Date: Apr 2004

Location: Wisconsin

Posts: 120

|

From what I have seen on the various forums is the fact most cant find it in stock. Untill supply is greater than demand I dont see how the MCW6k blocks are missing out on much.

Also I will agree that the PolarFLO blocks look nice but the retention plate to me would make the installed block look on par or less than that of the MCW6000 and between those two I would go with the best performing. That also is the only thing I dont like on Cathars new blocks, but it wont stop me from hopefully getting a total of 3 (1-G4 & 2-G5s). If the looks of it mounted with the included plate were to become an important feature I would have one made just for my mounting style out f someting like Lexan or Lucite. Last edited by Chew_Toy; 10-06-2004 at 03:25 PM. |

|

|

|

|

|

#205 | |

|

Cooling Savant

Join Date: Nov 2002

Location: portugal

Posts: 635

|

Quote:

I have waited for almoust 1 month for a mcw6000 or mcw6002, at www.pcdiga.com, but he just coudnt get it! too short of a supply. In the meantime a friend told me he would make me a clone ww, hell it works, so...

__________________

back. |

|

|

|

|

|

|

#206 | |

|

Thermophile

Join Date: Sep 2002

Location: Melbourne, Australia

Posts: 2,538

|

Quote:

Impossible to compete with the "gifters" or offshore if one wanted to actually make money. Getting blocks made up has opened my eyes to the huge disparities in machining costs that exist in the industry which many take for granted. Remove the "gifting" and "offshore" elements and the price I ask for is a total bargain. The machinists I use like me though because of the nature of the job at hand. Doing waterblocks is something that can be easily slotted in and around more commercially oriented jobs for the workshop, and I do understand why the "gifters" do it - purely because the machines would otherwise be idle and they'd have nothing to do - so the "gifters" may as well pay oneself a bargain rate as long as they're making something more than zero from the effort. I'm probably just too stubborn to give up a totally lost cause. If I expected profit and a sustainable living under the present manufacturing model I use, I'd have gone broke and closed up shop ages ago. |

|

|

|

|

|

|

#207 |

|

CoolingWorks Tech Guy Formerly "Unregistered"

Join Date: Dec 2000

Location: Posts: 2,371.493,106

Posts: 4,440

|

can't close a shop you don't have eh ?

lol |

|

|

|

|

|

#208 |

|

Cooling Neophyte

Join Date: Oct 2004

Location: Florida, USA

Posts: 35

|

Even if you charged 50% more Cathar, I and many others like me (I imagine) would still be willing to pay it. For a long term investment in utmost of quality components, premiums are worth it. I consider the current price for the G4/Storm to definitely be a great deal, and wouldn't consider spending the money on a lesser product.

|

|

|

|

|

|

#209 |

|

Thermophile

Join Date: Oct 2002

Location: U.S.A = Michigan

Posts: 1,243

|

I've got to have one of these G5's Cathar. You've outdone yourself man!

Can you offer a estimate of when the retail G5's will be ready? I also noted the greatly increased number of jets and cups in the G5 design vs G4. Along with the help of the silver base will the added jets/cups show a full 1c over the G4? As always you do the finest of work. Congrats once again on another great block. |

|

|

|

|

|

#210 |

|

Cooling Neophyte

Join Date: Aug 2004

Location: Scarsdale, NY, The U S of A

Posts: 27

|

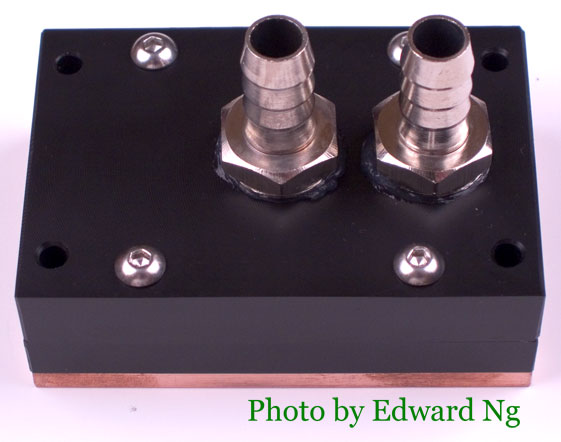

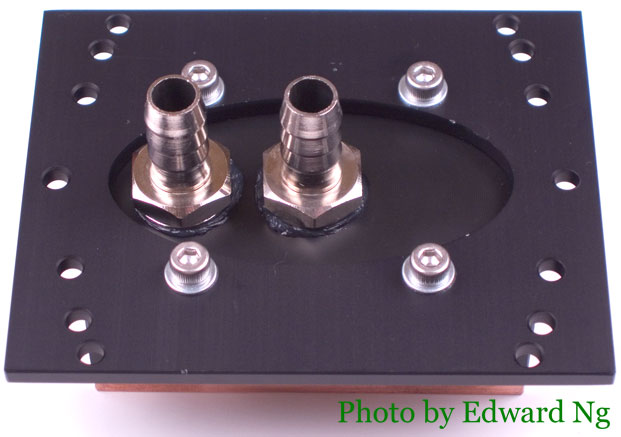

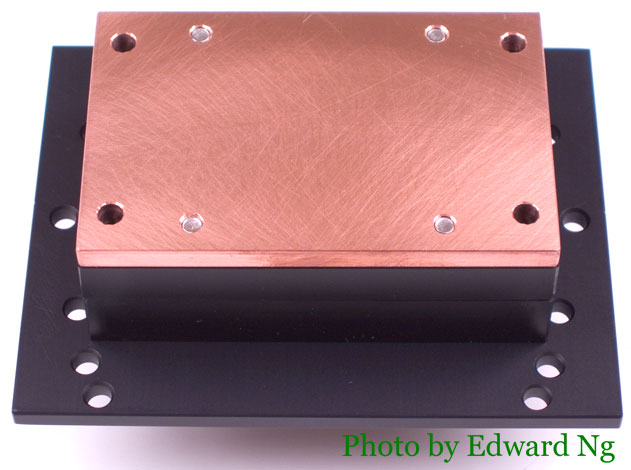

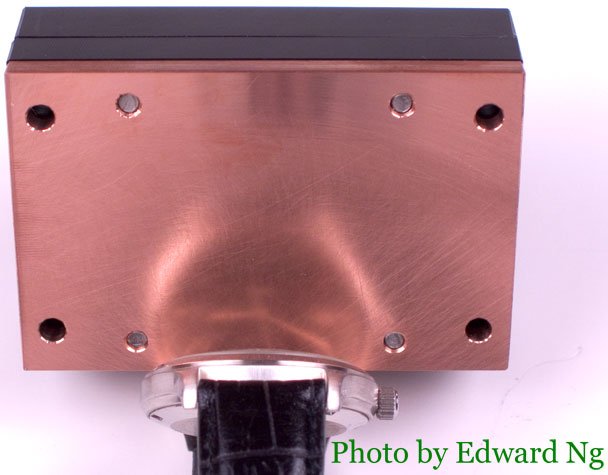

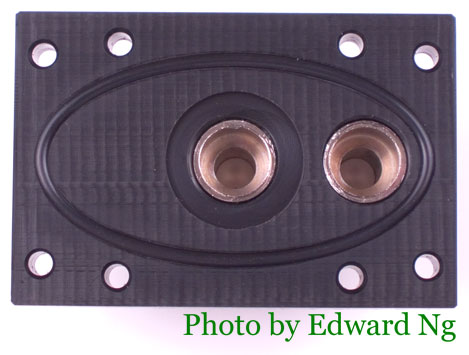

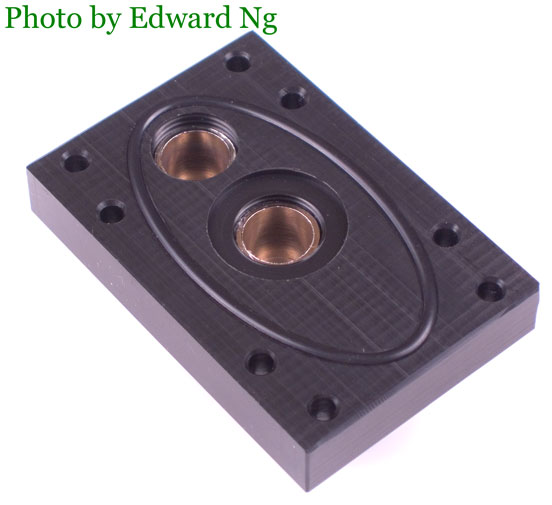

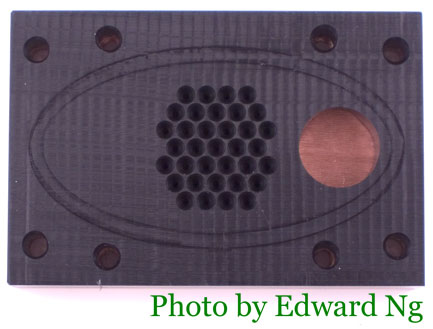

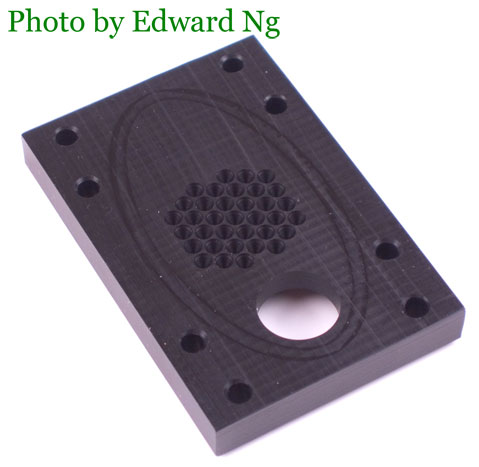

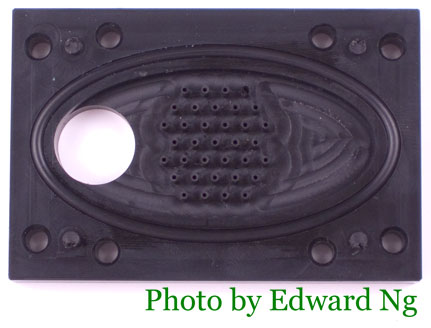

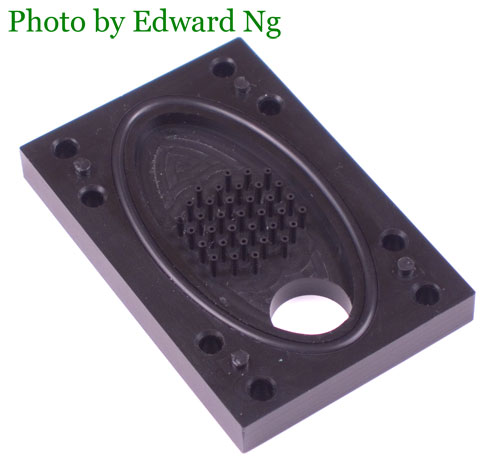

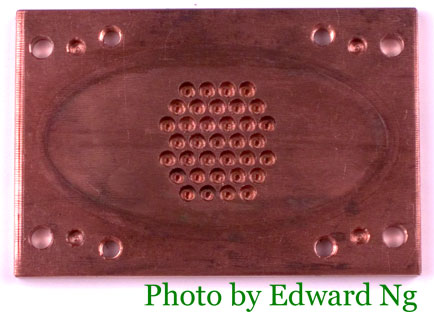

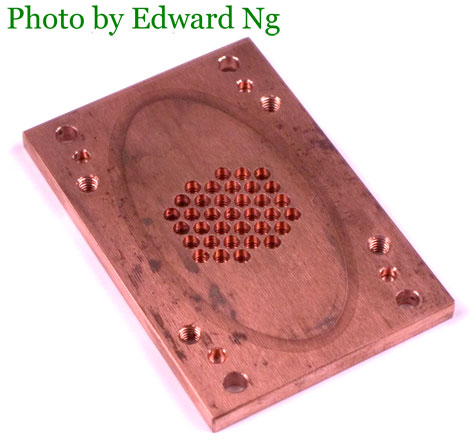

Stew has given me the green light to let you guys see the pics I took.

I have shots of the block in both, Socket A and universal fit modes, as well as pics of the necessary bolts that DFI LANParty UT NF3 250GB board owners will need. The pictures are purposefully overexposed in order to bring out the detail in the delrin parts. Please note that my block was sent out before the discovery was made of the land grid array 775 issues, so my block's base has not had the necessary portions adjusted to properly fit LGA775 boards, and is completely flat. Now, on with the pics--clicking on a picture on this post will bring up the full resolution version of the image. Please check out the full resolution shots!  SocketA, bolt-through mode.  Universal-fit mode.  Universal-fit, from underneath.  The contact surface; please note, once again, that this is not the final bottom plate, as the final baseplate has portions cut out to clear capacitors and other components in the proximity of the LGA775 sockets. Keep in mind that even though it's not mirror-smooth, the murky reflection shows zero distortion, indicative of a flat surface, which is more important than cosmetically perfect smoothness.  Under the inlet and outlet.  Just the top plate, with 3/8" fittings preinstalled.  Underneath again, at an angle.  Top side of the middle plate; the conical shape of the jet inlets, responsible for the acceleration of the fluid streaming in to the cups in the base plate, are visible.  Same shot, at an angle.  Underside of the middle plate; the jet outlets are clearly visible; they actually run part way into the cups in the base plate!  Same thing, different angle.  The copper base plate; notice the cups have small raised portions at the center for breaking up the dead flow zone at the center of the jettisoned streams; these little items supposedly make for a good portion of the Storm's improvement over Cascade.  Tilted.  Anyone else who wants to use the Storm G4 on DFI LANParty UT NF3 250GB boards will need bolts similar to these, which I got from Home Depot. If you're having trouble finding these in your neck of the woods, let me know and I can pick up a pack of them and send them to you for $2.50+shipping. They cost me $0.89+tax/pouch, but Home Depot isn't exactly a five minute walk from me, my car isn't particularly easy on fuel, and I need to take out time from my extremely busy day to not only go to Home Depot to get them, but also to stop by the post office to send them, and both places tend to have substantial waiting lines. This is only the case for first batch orders; with the second batch and any batches after that, Cathar will have bolts like these sourced and included, marking the primary difference from what's included with my block, other than the new, LGA775-compatible baseplate. -Ed EDIT: Captions added. Cathar, please let me know if you need any of them changed or removed. EDIT2: There have been reports of the pictures not showing up; if you have this problem, click here for the low resolution images, or here for the full resolution images. If it still doesn't work, "something error happens," with Earthlink's server, or the pathway between you and it, and I can't do anything about it. I checked my quota on my hosting and I've used less than 1GB out of 10 for my monthly limit, so I have no idea why it's acting up! EDIT3: Please don't kill this mirror; try the first links first!: Downsampled Versions (<600pixels wide) Full Resolution Versions (Just cropped from the raw shots) Last edited by Edward Ng; 10-10-2004 at 01:10 AM. |

|

|

|

|

|

#211 |

|

Cooling Savant

Join Date: Sep 2004

Location: USA

Posts: 148

|

wow ed you sure recieved that quickly.

have put it in your system yet? |

|

|

|

|

|

#212 | |

|

Cooling Neophyte

Join Date: Aug 2004

Location: Scarsdale, NY, The U S of A

Posts: 27

|

Quote:

I'm still not 100% sure if I will be able to include my Maze4 northbridge block into the NV-68's branch of my loop, due to the placement of the nForce3 chip on my new DFI LANParty UT NF3 250GB; it's really close to the GPU and its massive block. It won't kill me if I can't, since I can always install a plain air cooled sink on it, what with the front 120mm intake fan blowing right into that spot. It would also make routing my tubing much, much easier; picture it, the fittings on the NV-68 point up, the chipset is beneath the video card, and the radiator is installed behind the rear exhaust of the case, with the fittings poking in right underneath the PSU. I am still trying to figure out how the heck I'm supposed to run my tubing, even if the chipset block does fit with the video card and NV-68 block in place! -Ed |

|

|

|

|

|

|

#213 |

|

Cooling Savant

Join Date: Mar 2003

Location: southeast asia

Posts: 164

|

Stew

Besides the paint prob that you had, do you think this block would experience clogging? (Uber tinnie tiny holes, that's hard work) Anybody who has a Cascade experience any clogging? Maintenance every? I think this was asked before, but is there a difference in performance if it has 2 outlets like the WW? Thanks

Last edited by j813; 10-09-2004 at 04:11 AM. |

|

|

|

|

|

#214 |

|

Cooling Savant

Join Date: Mar 2003

Location: southeast asia

Posts: 164

|

oops 2 posts

|

|

|

|

|

|

#215 |

|

Big PlayerMaking Big Money

Join Date: Aug 2001

Location: irc.lostgeek.com #procooling.com

Posts: 4,782

|

If you clean your radiator/heatercore prior to using it and then filter the distilled water before it goes in the loop then it should be fine. If you're using some mix of stuff then you can always mix it up the night before, put the container in a full tub of the hottest water your bathtub can make, and verify nothing starts to precipitate out.

Also Cathar. No package here as of yet. Can you put a trace on it? Probably customs held it up again lol |

|

|

|

|

|

#216 |

|

Cooling Savant

Join Date: Feb 2003

Location: Willmar MN/Fargo ND

Posts: 504

|

Cathar, I thought you origially had this thing down to 10 minute machine time? or something similar to that?

It kinda made me wonder when I saw the price and a while back you said that the machine time was really low. Jon |

|

|

|

|

|

#217 |

|

Cooling Savant

Join Date: Sep 2004

Location: USA

Posts: 148

|

i think he was saying if you used a mold you'd only need 10 mins of machine time to clean it up.

|

|

|

|

|

|

#218 |

|

Cooling Savant

Join Date: Feb 2003

Location: Willmar MN/Fargo ND

Posts: 504

|

This was months ago when he first started talking about the design.

Jon |

|

|

|

|

|

#219 | |

|

Thermophile

Join Date: Sep 2002

Location: Melbourne, Australia

Posts: 2,538

|

Quote:

|

|

|

|

|

|

|

#220 | |

|

Cooling Savant

Join Date: Jun 2004

Location: Sweden

Posts: 152

|

Quote:

|

|

|

|

|

|

|

#221 | |

|

Thermophile

Join Date: Sep 2002

Location: Melbourne, Australia

Posts: 2,538

|

Quote:

|

|

|

|

|

|

|

#222 | |

|

Put up or Shut Up

Join Date: Dec 2001

Location: Spokane WA

Posts: 6,506

|

Quote:

. .  Anyway here is the basic drawing if the middle piece. All the red lines are tool paths. My mill came with a .dxf to G-Code converter. So basically I draw the tool paths I want to use and import it in .dxf format and it creates G-Code. Very very very sloppy G-Code but G-Code non the less. Unfortunately it only spits out 2D G-Code meaning only one pass (the first pass of about 5). So I have to create the next 4 passes changing alot of code..... One more obstacle it my mill can only run about an hour at a time before the motor overheats so I am going to have to break this up into about 5 different sets of code. Each set only doing one set of passes. My main reason for making my own version is to complete the project originally started here: http://forums.procooling.com/vbb/showthread.php?t=5476. Sorry the pics are gone, will try and find them and re-upload them when I get home. Anyway excellent work Cathar |

|

|

|

|

|

|

#223 | |

|

Thermophile

Join Date: Sep 2002

Location: Melbourne, Australia

Posts: 2,538

|

Quote:

Will be getting replacement G5 middle plates in the next 8-10 days. |

|

|

|

|

|

|

#224 |

|

Cooling Savant

Join Date: Jun 2004

Location: Sweden

Posts: 152

|

Cathar:> What do you think about thisone?

http://forums.procooling.com/vbb/att...achmentid=3876 going to have 7 chanels made like that, and the millbit is like yours, makes a top in the midel. |

|

|

|

|

|

#225 | |

|

Thermophile

Join Date: Sep 2002

Location: Melbourne, Australia

Posts: 2,538

|

Quote:

I'm not sure I understand what I'm looking at, and what you're asking of me. |

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

All times are GMT -5. The time now is 01:19 PM.