| ||

|

||

|

|||||||

| General Liquid/Water Cooling Discussion For discussion about Full Cooling System kits, or general cooling topics. Keep specific cooling items like pumps, radiators, etc... in their specific forums. |

|

| Thread Tools |

|

|

#1 |

|

Cooling Neophyte

Join Date: Nov 2003

Location: Hong Kong

Posts: 81

|

I understand that pump is likely to dump its portion of heat into the loop while the rest may go to air through its housing. Now, if I can efficiently and effectively increase the dissipation rate of those heat with some kind of devices (I mean the heat going to air), let say from 50% to 100%, will it be possible to lessen the heat dumped into water?

Last edited by alexwai; 08-23-2004 at 07:41 AM. |

|

|

|

|

|

#2 | |

|

Cooling Savant

Join Date: Sep 2003

Location: Vallentuna, Sweden

Posts: 410

|

Quote:

The question itself is flawed though. You won't be able to increase the rate of dissipation to air to 100%. But you could improve things if you consider it worthwhile. |

|

|

|

|

|

|

#3 |

|

Cooling Savant

Join Date: May 2002

Location: home

Posts: 365

|

Perhaps it would be helpful to look at what happens to the electrical energy that enters the pump. Essentially it gets converted to mechanical energy. In the process, there is some inefficiency. The motor consumes more energy than it delivers to the shaft. This inefficiency shows up as heat and in a submerged pump all of it enters the water. With an inline pump, almost all leaves via the surface of the motor housing. The "useful" energy leaving the motor via the shaft drives the impeller. All of this energy goes into the fluid. Some is in the form of a pressure rise and the rest is thermal. Without improving the pump efficiency there isn't much you'll do about this inefficiency.

|

|

|

|

|

|

#4 | |

|

Cooling Neophyte

Join Date: Nov 2003

Location: Hong Kong

Posts: 81

|

Quote:

|

|

|

|

|

|

|

#5 |

|

Cooling Neophyte

Join Date: Jun 2004

Location: New York

Posts: 48

|

I have a setup with a 120mm fan above my pump that I will be using in about a month. I'll post back some time as to whether the speed of the fan over the pump changes my overall cpu temp.

|

|

|

|

|

|

#6 |

|

Cooling Neophyte

Join Date: Nov 2003

Location: Hong Kong

Posts: 81

|

Any inputs?

|

|

|

|

|

|

#7 |

|

Cooling Savant

Join Date: Jan 2004

Location: orlando FL

Posts: 147

|

Alex the device you need to remove heat added by the pump is already included in the system, its the radiator itself. If you need to remove more heat, increase the airflow through the rad, or the rad surface area. This way you are concentrating specifically on the heat you are most concerned about. Its the simplest, and IMO therefore the best, solution.

__________________

www.nrlc.org |

|

|

|

|

|

#8 |

|

Thermophile

Join Date: Sep 2002

Location: Charlotte, NC

Posts: 1,014

|

^ what he said. You could be "watercooling" your pump instead of attempting to aircool it

It makes much more sense to just put more energy in cooling the radiator.

__________________

I have a nice computer. |

|

|

|

|

|

#9 |

|

Cooling Neophyte

Join Date: Nov 2003

Location: Hong Kong

Posts: 81

|

Let me put my question into more simple form.

Let say the original distribution of heat generation for the inline pump is : 80% dump into water while 20% to air. By whatever devices I use to cool down the housing , Can I make it to change 50% in water but 50% in air. Any solid date or sources to prove it? __________________ |

|

|

|

|

|

#10 |

|

Cooling Neophyte

Join Date: Mar 2004

Location: ohio

Posts: 51

|

ive "played around" with this idea too...pump cooling it does seem to help...some.

post #14 is where my "testing" starts.

__________________

JoeCamel is F@H for ....A CURE!! (40+ GHz) A64 Phase cooled: FX-55 @ 3204MHz (267x12) - MSI Neo2 - MachII - OCZ DDR Booster & VX @ 3.6V , 267 @ 2,2,2,5 1:1 - x800 XT-PE @ 665/608 - DD Maze4 with 172w TEC 14V TEC PSU - 500W X-Connect PSU A64 Water cooled: 3500 Venice @ 3000MHz (300x10) - DFI LP Ultra-D - Storm G5, D4 pump @ 16V, BIXII, 4x100+ CFM fans - OCZ VX @ 3.6V , 300 5:6 = 250 @ 2,2,2,6 - x850 XT @ 600/630 - socket A HSF & 80mm Tornado , copper mem sinks - OCZ 600W PSU |

|

|

|

|

|

#11 | |

|

Cooling Neophyte

Join Date: Nov 2003

Location: Hong Kong

Posts: 81

|

Quote:

|

|

|

|

|

|

|

#12 |

|

Cooling Savant

Join Date: May 2002

Location: home

Posts: 365

|

Not as you ask. You must understand that there's very little heat transfer from the motor casing to the fluid in an inline pump. Unless you improve the efficiency of the pump you can not change the amount of energy being transferred through the shaft, thus the amount of thermal energy put into the water from the pump.

Now you can "cool" the pump and some heat transfer may benefit, but you're talking about a situation analogous to a radiator. You're trying to remove thermal energy from the water. Look at the area of a radiator and the conductivity compared to the surface area and conductivity of a pump housing. If this isn't "pissing in the wind" or "barking up the wrong tree", then I don't know what is. With all due respect to Joe Camel, I hunch even he would tell you that the quality of the radiator setup dwarfs any gain to be had at "cooling" the pump. Having said all that, you certainly shouldn't lose any ground. IMHO it simply isn't worth the effort. |

|

|

|

|

|

#13 |

|

Put up or Shut Up

Join Date: Dec 2001

Location: Spokane WA

Posts: 6,506

|

That small all aluminum C-Systems pump D-Tek is selling got me thinking about milling a bunch of fins into it for a little extra cooling. Probably wouldn't help much but it might look kinda cool if nothing else.

|

|

|

|

|

|

#14 | |

|

Cooling Neophyte

Join Date: Nov 2003

Location: Hong Kong

Posts: 81

|

Quote:

|

|

|

|

|

|

|

#15 |

|

Thermophile

Join Date: Jun 2001

Location: The deserts of Tucson, Az

Posts: 1,264

|

Keep in mind that not all of the heating happens in the pump. Theres friction along the entire loop too, so in the end its a loseing battle. Maybe if you have some monster of a pump you could shave a few watts off by cooling the houseing, but keep in mind its made of plastic (or at best a thin aluminum shell with no fins). While a radiator is made of copper and does have fins. So a CFM of air on the plastic houseing is doing you a heck of a lot less then a CFM added to the radiator.

So while it can help, from an effciency/noise standpoint, just improve the radiator for best results. |

|

|

|

|

|

#16 | |

|

Thermophile

Join Date: Oct 2002

Location: U.S.A = Michigan

Posts: 1,243

|

Quote:

You could also use small passive finned coolers like used on SB ect bent, or cut into striips and attached with thermal epoxy to the housing to increase the surface area. Would allow the air flow over the pump to pull out heat much better. But the heat going into the water via direct contact with parts of the pump is still going to almost all go there. A interesting idea. |

|

|

|

|

|

|

#17 | |

|

Cooling Savant

Join Date: Apr 2004

Location: Wisconsin

Posts: 120

|

To me it seems trying to cool the pump of extra heat is like people that suggest making a water block with fins like a normal heat sink to aid cooling. Both to me are to quote myv65

Quote:

|

|

|

|

|

|

|

#18 |

|

Cooling Neophyte

Join Date: Sep 2004

Location: Oklahoma

Posts: 43

|

Also keep in mind why we use watercooling...

The ability of water to 'pick up' heat is much greater than air due to its thermal capacity. As such the water circulating through the pump will always be more efficient at pickup up heat than the air trying to cool the pump from the outside. Its the very reason we use water cooling instead of huge ornate heatsinks with huge fans on them- efficiency. While you will certainly be able to cool the pump via air cooling the heat that currently goes into the loop will largely remain the same. Now if you really wanted to try it I would suggest a submerged pump with a secondary cooling loop. It would indeed both remove more heat from the pump as well as extending the life up the pump by avoiding eventual thermal breakdown. The down side being the benefits from such a setup would be minimal at best. Now if a person was using a huge pump and wanted to stay beneath the effective 50watt pump threshhold that Cathar suggests then watercooling of the pump may just allow use of larger pumps without negative effects. |

|

|

|

|

|

#19 |

|

Thermophile

Join Date: Oct 2002

Location: U.S.A = Michigan

Posts: 1,243

|

I agree that improved cooling of the pump is only going to net a marginal gain. But in the case of the larger pumps like the MD20, Blueline/Panworld & Little Giant it may be worth doing for those try'n for the max possible in cooling.

And the cost of attaching some passive sinks to the pump housing of these larger pumps that can't be submerged would be quite small, and many of us have such sinks lay'n around anyway. Adding a fan blowing over the pump would be another step to take that costs little & would maximize the effect of the added sinks. Watercooling of the pump would be cost prohibative, for the gains made as Bugsmaster points out. |

|

|

|

|

|

#20 | |

|

Cooling Neophyte

Join Date: Nov 2004

Location: UK

Posts: 7

|

Quote:

Hi Redleader, you bring up an interesting point with friction in the pipes. I may have a triple benefit answer to it! (just maybe) Washing up liquid !  My Radiator is a Ford Sierra heater core that was given for free. I wanted to clean the waterways before use so did my best to remove most of the gunk and then left it running a couple of times overnight with small amount of washing up liquid in the pumping water (WaterBlock not included in cleaning loop!). When I put the system together I emptied the washing up water out and immediately replaced, it with ionised water and Asetek Anti Algae fluid and was astounded how well it worked with only an Eheim 1048 pump. Since then (6 months ago) I have wondered why the good result and perhaps its partially due to the washing up liquid! Current System specs: Abit AN7 motherboard Athlon 2500+ Mobile (2 months old from CPU City) Clocked from 1.86GHz to 2.7GHz @ 2.0V rock stable. 33C Idle, 40C load, 23C Ambient. CPU measured externally with the thermistor touching the CPU Die using one of these: http://store.over-clock.com/Adaptors___Connectors.html Arctic Silver 5 Asetek Antarctica 1/2" pipe water block Quite long 1/2" ID tube throughout with 1/2" OD fitting the waterblock. Eheim 1048 pump Ford Sierra Heatercore 1x120mm fan unknown CFM, not loud @12V Heatercore and Fan kept separated in a Stella Beer cardboard box to reduce turbulence. Sealed up with duct tape.  No Reservoir. From what I have been reading, the CPU is creating upwards of 140W The Antarctica Block is specced to shift 200W. My thoughts on why washing up liquid helps: 1) it acts as a surfactant, reducing the surface tension of the water so better adhesion to the Water Block and Radiator is made, dissipating more heat. Many Anti Algae solutions are also surfactants, maybe the washing up liquid helps fill some gaps or is a slightly different surfactant that complements the Anti Algae solution ? 2) Friction: The washing up liquid (even though quite mild) will have left traces on everything the water flowed through. Some of this will transfer to the newly added water block too. Something tells me that a very small amount of washing up liquid in the water and on the pipes helps reduce friction. I cant quanitfy this and would appreciate any help positive or negative. To try and gauge how much is in the system: When the pump isnt running, there are tiny white bubbles at any air cavity . They surround the small air cavity and do not fill it These bubbles remain for quite some time. 3) Algae. The 1/2" pipe used is Clear and theres a lot of it too (the airbox is routed to the other side of a loudspeaker). The pipes are directly under a window. There hasnt been a sniff of Algae yet in 6 months. I imagine that cleaning the system with Washing up liquid and then having a trace in the water is an effective algicide. It would be great if anyone would like to test this to see if any improvement happens. Before / after information would be nice. I have an open mind, so any comments will be much appreciated

|

|

|

|

|

|

|

#21 |

|

Cooling Savant

Join Date: Jul 2004

Location: Luyten 789-6

Posts: 108

|

I know this may sound weird as it is kind of opposite of you guys trying to do to cool your pump, but would there be any problem with me burying my MD-20Z in a wad of foam? i.e. zero airflow and some insulation too. I’m working on a design where the pump would be stuck in a corner and totally out of the ducted airflow. Any thoughts? If it is a problem I should be able to squeeze a Nexus 120mm in there.

Thanks, DrCR _________ |

|

|

|

|

|

#22 | |

|

Cooling Neophyte

Join Date: Nov 2004

Location: UK

Posts: 7

|

Quote:

Your pump gets warm at the moment. Give nowhere for the heat to go and it will get hotter until it is dead. Also if you give the heat nowhere to go other than the water, your newly superheated pump with be heating your water with nearly the power the pump uses. |

|

|

|

|

|

|

#23 |

|

Cooling Savant

Join Date: Jul 2004

Location: Luyten 789-6

Posts: 108

|

Yeah, very true.

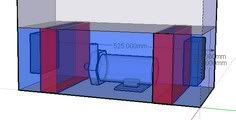

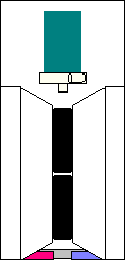

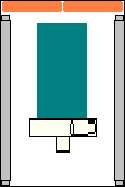

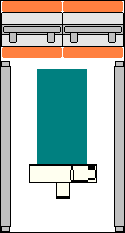

I'm getting ready to put together an external rad box. With one internal layout I had (Rev2), the pump would get almost no airflow, unless I added a 120mm fan just for it. With my latest revision airflow isn't an issue, but with heatercores on both sides, I may run into some noise issues. Just FYI Original concept:   The right side heatercore and fan should be swapped for the final version of this version. Rev2:  This is the one where the pump would roast. More brainstorm rather than final candidate. Rev3:  Rev3b:  You can read about it here if you feel so inclined: http://forums.silentpcreview.com/vie...=149759#149759 Thanks for your input Chernobyl. DrCR _________ |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

All times are GMT -5. The time now is 12:53 PM.