| ||

|

||

|

|||||||

| General Liquid/Water Cooling Discussion For discussion about Full Cooling System kits, or general cooling topics. Keep specific cooling items like pumps, radiators, etc... in their specific forums. |

|

| Thread Tools |

|

|

#1 |

|

Cooling Savant

Join Date: May 2002

Location: Ohio-State! <--Money Hussle! SUCKS

Posts: 292

|

I've been thinking for a WHILE, about what size and shape would be the most optimal for an airtrap. Through TONS of trial and error, I have not come as close as I would like. After countless hours looking at other people's ideas on what would suffice, I still don't really have an idea of what would say, be a standard airtrap/Res model for say, the avg person's Midtower. (Full towers don't count since just about anything can fit in them!) There are a few general problems I see with my and many designs:

1) SIZE- There are a lot of great designs out there, but they seem to be; either too small to effectively work and end up creating MORE air-bubbles than removing them, or they are just GIGANTIC and work well, but effectively suck up all the space in their cases, which makes repairing, cleaning and getting to stuff a huge burden of having to take out the trap etc... From experience, going bigger IS better! (Haha) For a simple reason of there is more space between the layer of air mixed w/ incoming water and water that has lost it's air mix at the lower "suction-zone." The smaller the airtrap, the less space between the suction point and the incoming air mixed water. Sounds sorta funny, but think of it as a cussioning zone. The further the air bubbles are away from the suction point, the more likely they will float to the top of the water container, and if there isn't much distance (liquid) between the suction point and the incoming air+water, more that likely, the air won't have a chance to escape to the top. It's a crude "science" explanation, which will probably warrant sticklers, but you should get the point. 2) SHAPE- There are all type of shapes Air-traps come in; The classic PVC- Joint (cylinder), Square, Rectangular, LONG tubes, even pop-bottle shapes! The problem I've had/seen with the shape is this; Most people, including myself, are thinking they are going to build a muli-purpose "Resevior/Air-trap," when in my trials, I've found that trying to have the function of both, didn't work too well. The function of a resevior is for holding EXTRA liquid for when your current supply runs out. Great idea, say for folks with an Evap-bong. Airtraps do 1 thing, TRAP AIR and let the water pass w/o it. But when I tried to mix the 2 ideas it seems to make matters worse. Why? Well why is this... My system has a pretty good amount of flowage coming from the CPU to the Air-trap/Res, and it holds about a cup of water. I keep it about 90% full and it works great (EXCEPT the foam problems), BUT let that 90% fall to about 75% and I'm in AIR BUBBLE CITY! The water hits the top of the Lucite, then has to fall a much greater distance, which creates air bubbles, which instead of rising to the top, like before, now get sucked in with the current b/c there isn't as much less-turbulent water between it and the suction-"zone." I've had to redo and REDO my designs in order to try and compensate for the increased amount of turbulent water resulting from lack of total water amount. I mean, what's the point of having a resevior that you ALWAYS have to have near full, in order to prevent bubbles from occuring?! Again, BIGGER is better this case of trying to mix the 2 ideas. Just like the long-thin-tube-types, you HAVE to have as much water in them as possible, or else, you'll end up creating more bubbles than you started with. Of course "I could be wrong," since this is the "PRO-forums," in which there is ALWAYS someone out to prove your theories false, but I hope that my problems will lead other designs that will not create more bubbles than you started out having. If anyone has some radically SIMPLE design that could serve as both a res/Trap, plz let me know!  BTW- I wonder, since there is a section that is specifically about water block talk, how well would a section be for posting airtrap/Res designs go? Making a nice Trap/Res is NOT as simple as it seems. :/

__________________

XP 1600+ AGOIA-Y (GreenLabel, UNLOCKED!@/ NF7-S 2.0/ PC 2700 DDR 10.5*172FSB(1806/ 1991 high), Vcore 1.792...@84.95Watts --86' Chevette Heater Core --1/2" Vinyl tubes --Via1300-Stealth Mod(QUIET!)  ---Home made copper-tube block ---PVC small internal res |

|

|

|

|

|

#2 | |

|

Cooling Savant

Join Date: Feb 2001

Location: So Cal

Posts: 125

|

Quote:

__________________

Plumber's Goop: The Watercooler's Duct Tape |

|

|

|

|

|

|

#3 |

|

Cooling Savant

Join Date: May 2002

Location: Ohio-State! <--Money Hussle! SUCKS

Posts: 292

|

WOW, now how did I KNOW someone, yes SOMEONE would be the first to post such an intresting response... damn ProForums!

__________________

XP 1600+ AGOIA-Y (GreenLabel, UNLOCKED!@/ NF7-S 2.0/ PC 2700 DDR 10.5*172FSB(1806/ 1991 high), Vcore 1.792...@84.95Watts --86' Chevette Heater Core --1/2" Vinyl tubes --Via1300-Stealth Mod(QUIET!)  ---Home made copper-tube block ---PVC small internal res |

|

|

|

|

|

#4 |

|

Responsible for 2%

of all the posts here. Join Date: May 2002

Location: Texas, U.S.A.

Posts: 8,302

|

I've given this airtrap some thought, and came up with the one you know:

http://forums.procooling.com/vbb/sho...&threadid=5613 with 3/4" PVC parts, it really isn't flow restrictive at all, and clears air in about 10 seconds, even in the smaller size. Everything is optional: if you don't want a hole in the top of your case, that's fine. If you don't want clear tubing, use normal white PVC. If you don't want the interchangeable barbs, just go straight for the 1/2 NPT connections, teflon/screw in your polypropylene (grey) barbs, and forget about it. It's all non-metallic, so not reactive with anything. The cap (with Teflon) is easily removeable, and makes an excellent seal. Also, if you really don't want the U shape, then just use the tee, and connect a barb horizontally. I'll be hooking up my flowmeter to it, which will screw right into it. I'll also be adding a filter: http://forums.procooling.com/vbb/sho...&threadid=7263 It'll fit perfectly, as there's a ring inside the fitting to hold it. A simple tab will allow me to pull out the filter for cleaning. Now I'm sure that if I gave it more thought, I could come up with a better solution. The trick really, is to ideally make the water travel horizontally, over a wide area, to allow the air to bubble up, with a relatively slow flow speed (not flow rate), or over a relatively long length. |

|

|

|

|

|

#5 |

|

Cooling Savant

Join Date: May 2002

Location: Ohio-State! <--Money Hussle! SUCKS

Posts: 292

|

THANK you BB2K... I was actually waiting for YOU to respond

Always nice to get good advice from ya thanks Always nice to get good advice from ya thanks

__________________

XP 1600+ AGOIA-Y (GreenLabel, UNLOCKED!@/ NF7-S 2.0/ PC 2700 DDR 10.5*172FSB(1806/ 1991 high), Vcore 1.792...@84.95Watts --86' Chevette Heater Core --1/2" Vinyl tubes --Via1300-Stealth Mod(QUIET!)  ---Home made copper-tube block ---PVC small internal res |

|

|

|

|

|

#6 |

|

Cooling Savant

Join Date: Apr 2002

Location: Houston, TX

Posts: 192

|

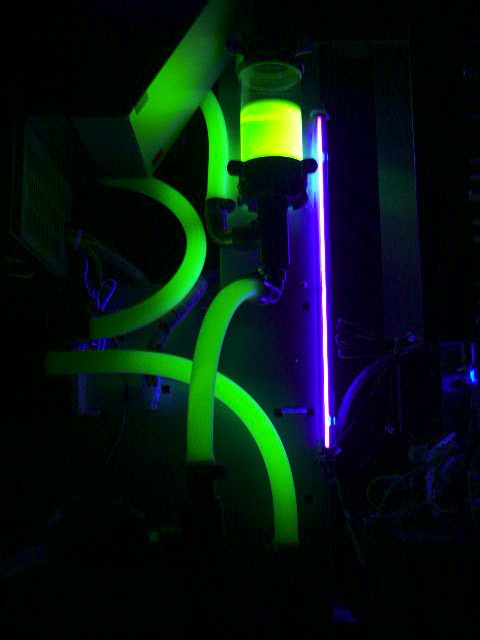

My resevoir/air trap is as described in the pic below. It works quite well it seems, mind you it's mounted outside the case on my "watercooling box".

|

|

|

|

|

|

#7 |

|

Cooling Savant

Join Date: Apr 2003

Location: Blackburn / Dundee

Posts: 451

|

I know it isn't the best drawing but my res works great as an air trap.... the preasure from the system keeps it the only air pocket evn though it isn't at the highest point of the system.

The real hope naturally is for the optimum design of an airtrap. |

|

|

|

|

|

#8 | |

|

Responsible for 2%

of all the posts here. Join Date: May 2002

Location: Texas, U.S.A.

Posts: 8,302

|

Quote:

If one looks hard enough, you can actually find that tee with threaded connections, which makes the whole thing a glueless operation: just Teflon tape. I can only recomend "3/4" PVC parts, because of the large unrestricted ID of it, which is perfect for slowing down the flow to where the air can get out. "1/2" parts would be too restrictive, and anything bigger than "3/4" is gonna get you into issues of how to fit it inside the case. Threaded adapters are also available, to convert one size thread to another. I've used 3/4 -> 1/2 1 1/2 -> 1/2 1 1/2 -> 3/4 and even a threaded 1 1/2" nylon adapter with a 3/4" barb on it. Now back to a better design: I'd run a tube across the top of the case, either round or square, maybe even clear, with an inlet outlet at either end, and an opening (fill point) that'd stick out through the top of the case. 1 to 2" ought to do it, just enough not to interfere with the second 5 1/4 drive bay. The opening should be farthest away from the inlet, and the further, the better. |

|

|

|

|

|

|

#9 |

|

Cooling Savant

Join Date: May 2001

Location: Brussels - Belgium

Posts: 232

|

This is the one who worked best for me: (50mm OD - 44mm ID)

I made already 7 of them, in whatever length you want (although lenght doesn't matter... Ask my girlfriend  ) )Bleeds in about an hour.     See alsohere CD

__________________

My website: http://www.turbokeu.com Backup website: http://www2.turbokeu.com My company: http://www.kdcs.be |

|

|

|

|

|

#10 |

|

Cooling Savant

Join Date: May 2002

Location: Ohio-State! <--Money Hussle! SUCKS

Posts: 292

|

Hey all, THANKS 4 the tips and responses (hard to come by now a days, good ones at least), I'm going to try playing around with all of your ideas...

BTW- Turbokeu, man, you've got a KICKASS website!!!  I wish I had some of those electrical skills you possess! Thanks for the advice! I'm going to try and hunt down some of that plexi-tubing at the local hardware stores and hope they carry larger sizes and make my own sorta like yours! Thanks again everyone. I wish I had some of those electrical skills you possess! Thanks for the advice! I'm going to try and hunt down some of that plexi-tubing at the local hardware stores and hope they carry larger sizes and make my own sorta like yours! Thanks again everyone.

__________________

XP 1600+ AGOIA-Y (GreenLabel, UNLOCKED!@/ NF7-S 2.0/ PC 2700 DDR 10.5*172FSB(1806/ 1991 high), Vcore 1.792...@84.95Watts --86' Chevette Heater Core --1/2" Vinyl tubes --Via1300-Stealth Mod(QUIET!)  ---Home made copper-tube block ---PVC small internal res |

|

|

|

|

|

#11 |

|

Cooling Neophyte

Join Date: Jul 2003

Location: Washington

Posts: 48

|

After seeing those pics Turbo, I have decided to introduce a different resovoir+air trap into my system. Thanks!

|

|

|

|

|

|

#12 | |

|

Cooling Savant

Join Date: Dec 2002

Location: Houston, TX, USA

Posts: 221

|

Quote:

something like Razor6's design will work well, but it is not optimal, as bubbles can be sucked to the side before getting a chance to rise... In Boli's design, the bubbles owuld have to get sucked down - much more difficult. |

|

|

|

|

|

|

#13 |

|

Cooling Savant

Join Date: Apr 2002

Location: Houston, TX

Posts: 192

|

I thought about whether I should have the water come in at the bottom or the side and one deciding factor was the tendency to sometimes form a vortex if the outlet was at the bottom. Althornin, you mention the bubbles being sucked to the side and not being able to rise. Wouldn't this problem also manifest itself if the flow were reversed? The bubbles will flow wherever the water flows. Has anyone tested the two flow directions?

|

|

|

|

|

|

#14 |

|

Cooling Savant

Join Date: May 2001

Location: Brussels - Belgium

Posts: 232

|

I will try to explain why I think my airtrap works so well.

(Sorry for my poor paint skills...  ) ) The 1/2" tubing is connected to a 20mm ID (3/4") T-part, thus slowing down the water velocity. The water entering the T is then divided in two streams: - a little stream going up in the "reservoir". - a big stream going down by the suction of the pump. As most of you know, air trapped in the circuit is "mulched" into microscopic air bells by the pumps impeller when passing through it. Those microscopic air bells (more like foam) need some time to go up and reach the water surface. The little water stream entering the reservoir creates a very slow vortex (you can see it when you look very close) before returning into the T again. This vortex gives the microscopic bells the time to reach the water surface. At every passage of the water through the T, a part of the water looses its air. From a "milky" solution my airtrap clears the water in about an hour, leaving just a layer of foam for a couple of hours on the surface of the water in the reservoir. CD

__________________

My website: http://www.turbokeu.com Backup website: http://www2.turbokeu.com My company: http://www.kdcs.be Last edited by Turbokeu; 07-15-2003 at 07:53 AM. |

|

|

|

|

|

#15 |

|

Responsible for 2%

of all the posts here. Join Date: May 2002

Location: Texas, U.S.A.

Posts: 8,302

|

That's "spot on"!

In my design attempts, I can't recomend strongly enough an increase in diameter of the tee. Going from 1/2" to "3/4" is extremely easy to do. In fact it can be done without having to glue a single part, just screwing them together. At that point, whatever sits on top of the tee is just eye candy, but any clear part that lets us see the state of the coolant is good, IMO. |

|

|

|

|

|

#16 |

|

Pro/Staff

Join Date: Oct 2001

Location: Klamath Falls, OR

Posts: 1,439

|

Turbokeu has some of the best looking airtrap/reservoirs I've ever seen, but I disagree with his design.

I have an airtrap that looks very similar but I have the inlet going into the main res chamber instead of at the top. My bubbles clear out in less than five minutes if I have enough liquid in the system. The reason that I disagree with Turbokeu is that I believe that the key to removing air is to reduce velocity by increasing the cross-section of the flow. Having a wide body airtrap allows the water to slow down without presenting too much flow impedance. Right-angle bends are murder on your available head pressure. From what I've read and seen, a single right-angle bend is the same as having (I'm trying to remember the exact figure, so forgive me if I'm totally off) an extra 6 or 12 feet of tubing. This is what I have right now (although the electronics are updated quite a bit):  . .So, I when I want to fill the system, I lift the res up like this:  and then pour. I don't think it is the ideal setup though. My ideal setup would be to have a purely horizontal flow through the airtrap, like setting a 2-liter pepsi bottle on its side, running water horizontally through it, and then tapping the top to add water and remove air. It takes up a lot of space that way though. I do have to agree with V12|V12 though: it is a pain to have to keep refilling the system to avoid creating the bubbles. I never took the time to properly seal the top of my airtrap (it needs a gasket) so I lose quite a bit due to evaporation: I end up putting about 1/2 cup of coolant in there every six months. And when it's low on coolant, the high velocity input into the res splashes, swirls around and sucks the bubbles right on into the system. It's annoying. |

|

|

|

|

|

#17 |

|

Cooling Savant

Join Date: Mar 2002

Location: Oregon, USA

Posts: 230

|

Look at what a local shopping trip procured:

grr, peice of junk digicam It is a food storage container with a rubber seal on the lid. Plus it is clear, an added bonus  Cost me all of $2  Add some barbs and I'll have me an airtrap  Only thing I'm worried about it the fact that it is a little large, I may be cutting it down a bit to fit into my case, or I may not even use it. We'll see...

__________________

Signing out... Yo-DUH_87 If it works, fix it until it's broke! Then, after it's broke, add duct tape! Affordable webhosting! |

|

|

|

|

|

#18 | |

|

Cooling Savant

Join Date: Dec 2002

Location: Houston, TX, USA

Posts: 221

|

Quote:

Your design is adequate, and looks very nice - but it is far from optimal. |

|

|

|

|

|

|

#19 |

|

Cooling Savant

Join Date: May 2002

Location: Ohio-State! <--Money Hussle! SUCKS

Posts: 292

|

Wow, I love all the responses... I dunno, for some people, designing a working Res, and Airtrap come easy, but I'm talking about ALL-IN-ONE. Like Turbo's... It's not as easy as it seems, because a Res AND an Airtrap have 2 diff functions and the way the water flows in them is very different, IF you want effectiveness.

IE: Resevior's function is to have extra water for the system loop, not to trap air, but it does in a small way, b/c water HAS to flow through it and at least a small amount will release the micro-bubbles. (Really general statement) AirTRAP, alone, does 1 thing well, trap the most possible amount of incoming air in the water, while letting more non-air saturated pass. The problem is, if you don't have a set/certain pre-existing amount of water in it, it won't do it's job very effectively... and in most cases I have experimented with, it will create MORE airbubbles than you originally started with!  Another VERY IMPORTANT factor I've found is inlet and outlet placement. This factor can make or BREAK your chances of having a nice combination of the 2. ---For a Res, usually it can be a larger container on top of a "T"-splitter, since all you want is extra water to be availible. --For an Airtrap, like BigBen's, you just need the inlet outlet to be as far away as possible from the outlet in order to avoid bubbles getting sucked back down and "mulched" up even more! --For BOTH, it gets tricky sorta like turbo's takes a good hour, which ain't bad, but for some of us, like myself, UUUGH! I want to SEE the bubble clear up in like 10miN, lol! But that's NOT going to happen unless you've got a HUGE res! Take BigBen's idea and on the outlet side, make the tube say 3.5Wx3.5" going to the pump, and then you'd have BOTH and wit would be very effective! But I have very limited space. Also, if you want to have BOTH and don't want the largeness factor, you'll just have to sacrifice with some flow restriction and TIME it takes to clear the system, but most people have ~300GPH pumps, so a few bends here and there are not going to kill your flowates. I'm NO expert at this, and I could be incorrect, but this is just some of the stuff I have noticed in the trials of building the optimal Res/Air-Trap... I'm going to MS-Paint up a few ideas I just got and post soon... thanks all!

__________________

XP 1600+ AGOIA-Y (GreenLabel, UNLOCKED!@/ NF7-S 2.0/ PC 2700 DDR 10.5*172FSB(1806/ 1991 high), Vcore 1.792...@84.95Watts --86' Chevette Heater Core --1/2" Vinyl tubes --Via1300-Stealth Mod(QUIET!)  ---Home made copper-tube block ---PVC small internal res |

|

|

|

|

|

#20 |

|

Cooling Neophyte

Join Date: Apr 2002

Location: Illinois

Posts: 94

|

I used a large filter housing for mine since its in a full tower. No glued seams, just O-rings and a gasket. I am using the 1/2" OD hoses for the Swiftech pushlock fittings, so 3/8" ID copper was fine for me. Larger tubing would just require a larger fitting and hole in the bottom of the res. It bleeds the air out very quickly. The smooth bend copper elbows don't harm flow much, not like the sharp right turn plastic fittings. |

|

|

|

|

|

#21 | |

|

Cooling Savant

Join Date: Dec 2002

Location: Houston, TX, USA

Posts: 221

|

Quote:

|

|

|

|

|

|

|

#22 | ||||

|

Cooling Savant

Join Date: May 2001

Location: Brussels - Belgium

Posts: 232

|

Quote:

The little upgoing stream to the reservoir is the one that actually traps air. The big downgoing stream simply goes back to the pump. I didn't want the complete flow to pass through the reservoir, in which case the air bubbles are sucked back into the outlet (I tried) I observed the movement of the water and the air bells in the reservoir with a torch (when the coolant was still milky): I can see tiny bubbles coming out of the T, going up and turning around slowly, but I don't see bubbles being sucked back in the T. Quote:

Quote:

The curing of your thermal paste takes MUCH longer... Quote:

CD

__________________

My website: http://www.turbokeu.com Backup website: http://www2.turbokeu.com My company: http://www.kdcs.be Last edited by Turbokeu; 07-16-2003 at 07:51 AM. |

||||

|

|

|

|

|

#23 | ||

|

Cooling Savant

Join Date: May 2001

Location: Brussels - Belgium

Posts: 232

|

Quote:

Quote:

CD

__________________

My website: http://www.turbokeu.com Backup website: http://www2.turbokeu.com My company: http://www.kdcs.be |

||

|

|

|

|

|

#24 |

|

Responsible for 2%

of all the posts here. Join Date: May 2002

Location: Texas, U.S.A.

Posts: 8,302

|

Well, I for one am certainly going to have to take a closer look at my plans: I've got 3 high points where air could get trapped, and only one of them is an airtrap.

I'm thinking about mounting my heatercore upside down, so that it can drain easily, and have the tubes at the bottom, instead of the top, but that doesn't solve the problem either.:shrug: and could actually make it worse! Then I'll have 1/2" copper pipes, running up and down, to feed the power array. I think I can simply add a removeable cap on top of it. Maybe I ought to simply weld a drain cap into the bottom tank of the heatercore. |

|

|

|

|

|

#25 | |

|

Cooling Savant

Join Date: May 2002

Location: Ohio-State! <--Money Hussle! SUCKS

Posts: 292

|

Quote:

and mine doesn't have the 90° elbow. Good work! and mine doesn't have the 90° elbow. Good work!Folks, I think I have got it; a Res with the efficiency of an air-trap! Well not quite the efficiency, but much better than a regular Res and much less turbulent than an air-trap. It's sorta simple... Just take Turbo's short but wide design and mate it with BigBen's "T". It would be like I posted before. Basically a larger Tube of some kind on the top of at LEAST a 1" or larger T-splitter. With the "large" opening of the 1+" there will be plenty of space for a significant amount of air+water mix to escape to the top. Okay it's not "huge," but consider how much more surface area 1" is over the .37 of a 1/2-ID tube. And if your like me, I'm going to try and make the "T" as large as possible! Though it will take more time to trap air than a standard air-trap, it should do pretty well. Also, the larger tube on the top will provide PLENTY of extra water. Turbulence, should not be as much of a factor as with an Air-Trap, unless you have something diverting a significant amount of flow up in to the Res... Another idea I came up with is; since most of use will not be letting the water level in our Res's (etc.) get to such a low level that bubbles start to get sucked back down into the system, you could put a little (flat) piece of plastic at an angle/vertical in the middle of the "T," so that a bit more of the incoming air+water will be diverted up into the Res, but not so much that it will start to "fountain" up and create splashing/turbulence. If I had any AutoCad skills I'd make a nice pic, but MS-Paint will have to do... :/ *With the vertical one, I figured that the higher or taller the piece of plastic is, the less chance that the incoming water will be pulled directly back down in the system, which will give the air-bubbles a little more time to float to freedom!? And again my pseudo-fluid-dynamics ideas are not that of fact, just some brain storming that I was doing early this morning... I'm not sure which one I'll go with, but I think it might be the vertical idea. Oh, one more note; if you play around with the depth that the plastic piece protrudes down into the "T," to more or less turbulence and overall amount of incoming water is diverted into the Res... Good luck!

__________________

XP 1600+ AGOIA-Y (GreenLabel, UNLOCKED!@/ NF7-S 2.0/ PC 2700 DDR 10.5*172FSB(1806/ 1991 high), Vcore 1.792...@84.95Watts --86' Chevette Heater Core --1/2" Vinyl tubes --Via1300-Stealth Mod(QUIET!)  ---Home made copper-tube block ---PVC small internal res |

|

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

All times are GMT -5. The time now is 04:24 PM.