| ||

|

||

|

|||||||

| General Liquid/Water Cooling Discussion For discussion about Full Cooling System kits, or general cooling topics. Keep specific cooling items like pumps, radiators, etc... in their specific forums. |

|

| Thread Tools |

|

|

#1 |

|

Cooling Savant

Join Date: Mar 2003

Location: St. Paul, Minnesota, USA

Posts: 123

|

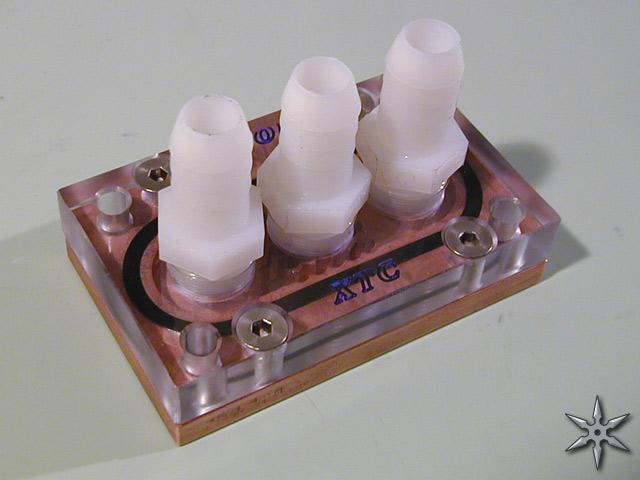

Do you slightly more experienced folks think this is a good looking block for $40, or if I could get possibly better performance with something else for a comparable price?

I'm not looking for super turbocharged amazing cooling, but I want something that can do better than the lame common blocks on the market (like swiftech, koolance, etc). The double outlet is important for my design, so if you have a different block to recommend, it would have to fall in that category. I'll be driving the system with an Eheim 1250 and there will be an 8mm tubed innovatek chipset/GF4 block on each of the CPU block's outputs, which will then reconverge and go back up to 1/2" tubing with a custom wye. Big 2x120mm fan heatercore to exchange heat.

__________________

Abit NF7-S ... xp1800+ ... Abit GF4ti4200 ... Maxtor 120gb SATA150 Currently gathering parts to water cool everything! (read about the project) |

|

|

|

|

|

#2 |

|

Cooling Neophyte

Join Date: Oct 2003

Location: Norway

Posts: 2

|

Looks like a lumpy whitewater or the dangerden rbx without the nossle to get the flow up.

__________________

Unlike most of you, I am not a nut. |

|

|

|

|

|

#3 |

|

Cooling Savant

Join Date: Mar 2003

Location: Ohio, U.S.A.

Posts: 177

|

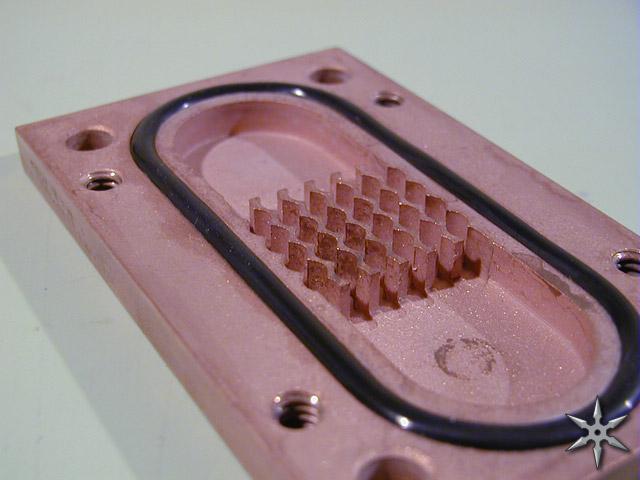

well, i wouldn't call myself an expert or anything, but a couple of observations; i'd spend the extra $10 and get an RBX from dangerden. the barbs on the XTC seem very close, getting hoses on (and then clamping them) would be a major pita. also, the mounting holes for the top are counter-sunk (not a good thing), and VERY close to the edge, both of which make me nervous. and i'm guessing the RBX will out-perform the XTC, which you mentioned you aren't very concerned with, but hey, it never hurts, right? so that's just my $0.02

|

|

|

|

|

|

#4 |

|

Cooling Savant

Join Date: Mar 2003

Location: MO

Posts: 781

|

Dang, Zog! You posted most of my comments before I could!

The currect lack of nozzles is a problem. My other concern is structural - the base plate is very thin, does the top contact the top of the fins to reinforce things like it should? I can't quite tell from the pictures... If you buy, definitely change out the countersunk screws and make a yourself a nozzle. |

|

|

|

|

|

#5 |

|

Cooling Savant

Join Date: Mar 2003

Location: St. Paul, Minnesota, USA

Posts: 123

|

hmm. I was considering making a second layer to sandwich into the mix with a nozzle, but you are right about the closeness fo the barbs.

I do like the aesthetics of the RBX compared to the XTC. I'm a sucker for stuff that looks nice, so I would have a hard time looking at that XTC now that I've seen some close-ups of the RBX. sweet block, and the performace will probably be a little better. Potential performance edge and major visual appeal advantage make the RBX worth the extra $10 in my mind. Thanks for pointing me at it. I see that cooltechnica has them for about $51, so I might as well get one there along with the other things I'll be needing.

__________________

Abit NF7-S ... xp1800+ ... Abit GF4ti4200 ... Maxtor 120gb SATA150 Currently gathering parts to water cool everything! (read about the project) |

|

|

|

|

|

#6 |

|

Cooling Savant

Join Date: Feb 2002

Location: Oxford University, UK

Posts: 452

|

The poly topped dtek white water can now be had for $49.99. It is a pretty darn good block if you ask me.

Also, do you already have the innovatek blocks. Nothing against them, but I would suggest keeping the whole system in 1/2" ID. When you say that the innovatek blocks are 8mm, is that ID or OD. A thought for you. Two 8mm ID hoses is more restrictive than a single 1/2"ID hose. If it's OD, then they are a LOT more restrictive. http://www.dtekcustoms.com/index.asp...ROD&ProdID=106 8-ball

__________________

For those who believe that water needs to travel slowly through the radiator for optimum performance, read the following thread. READ ALL OF THIS!!!! |

|

|

|

|

|

#7 | |

|

Cooling Savant

Join Date: Mar 2003

Location: St. Paul, Minnesota, USA

Posts: 123

|

Quote:

I know this is more restrictive than running all the blocks in series with 1/2", but I'm sure I would lose a lot by dropping the 1/2" to 3/8" to make it into and out of the innovatek blocks. I don't feel like buying or making new chipset/GPU blocks at the moment, so I'm hoping this solution will work. Advice? Suggestions?

__________________

Abit NF7-S ... xp1800+ ... Abit GF4ti4200 ... Maxtor 120gb SATA150 Currently gathering parts to water cool everything! (read about the project) |

|

|

|

|

|

|

#8 |

|

Cooling Savant

Join Date: Oct 2003

Location: Almere, The Netherlands (Europe)

Posts: 262

|

Your setup will work just fine.... BUT:

Changing the barbs at the innovatec to a 3/8 won't do the trick. You fix the hose issue (as 2 x 3/8 = 1/2) but your problem will be that the innovatec's are internally designed to work with 6.5mm  I'm using a similar setup, but I opened the Innovatec, and it's just one solid plate of copper. Take a drill or a dremel and make a flow path. After I did this, it was working just as good (flow wise) as my D-Tec Z chipset block. (I'm using the innovatec for my GPU, as I'm not OC'ing my Gforce4)

__________________

If it get's hot, it needs to be watercooled! |

|

|

|

|

|

#9 | |

|

Cooling Savant

Join Date: Mar 2003

Location: St. Paul, Minnesota, USA

Posts: 123

|

Quote:

I built a jig for my moto tool that allows it to be lowered down sort of like a chop saw. I figure I can clamp the copper plate down to the jig and grind a series of closely spaced grooves into the copper. What is the best kind of dremel disc for cutting into copper? I tried the rig out on a scrap of aluminum barstock, and the reinforced steel cut-off wheel I had on it bogged down A LOT because there was little room to clear chips. I figure copper will behave similarly, especially when I need to cut in about 1/4". Advice on this?

__________________

Abit NF7-S ... xp1800+ ... Abit GF4ti4200 ... Maxtor 120gb SATA150 Currently gathering parts to water cool everything! (read about the project) |

|

|

|

|

|

|

#10 |

|

Cooling Savant

Join Date: Jun 2003

Location: North Billerica, MA, USA

Posts: 451

|

Never really tried a Dremel on copper, as I had other methods of cutting it, but my preference for Dremel disks are the fiber reinforced ones. I find them far more durable than the composite disks that shatter at the least sign of side loading.

Gooserider

__________________

Designing system, will have Tyan S2468UGN Dual Athlon MOBO, SCSI HDDS, other goodies. Will run LINUX only. Want to have silent running, minimal fans, and water cooled. Probably not OC'c |

|

|

|

|

|

#11 |

|

Put up or Shut Up

Join Date: Dec 2001

Location: Spokane WA

Posts: 6,506

|

Looks familiar. http://www.customcomp.us/forums/view...c273817cc4ce13

|

|

|

|

|

|

#12 |

|

Cooling Savant

Join Date: Mar 2003

Location: St. Paul, Minnesota, USA

Posts: 123

|

Indeed it does, Jaydee.

You know what they say about imitation being a form of flattery... You know what they say about imitation being a form of flattery...I tried the dremel jig, and after a half hour of grinding, I had four notches partially done on one of the blocks. It would have probably taken me a weekend of work and a whole lot of cut off wheels, so I gave up and mooched some time on a mill from my former high school industrial tech teacher (a real good guy). The jig in action:  The melted plastic liner on the bottom of the block after 30 minutes of dremeling (I had to pry the block off of the wooden jig. oops)  Here's the after shot of the milled blocks right before I deburred and cleaned them up:  The base thickness inside the milled area is right around 1/8" now. That ought to get plenty of water through. I wish I could have found a viable way to grind those fins in to take advantage of the better heat transfer, but this will do well enough for my purposes. These are only cooling the NF7-S northbridge and GF4TI4200 GPU after all. See more info on the ongoing project as a whole here: http://www.basementfreaks.com/member.../watercooling/ I think it's time to start discussing in a new thread.

__________________

Abit NF7-S ... xp1800+ ... Abit GF4ti4200 ... Maxtor 120gb SATA150 Currently gathering parts to water cool everything! (read about the project) |

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|

All times are GMT -5. The time now is 01:37 PM.